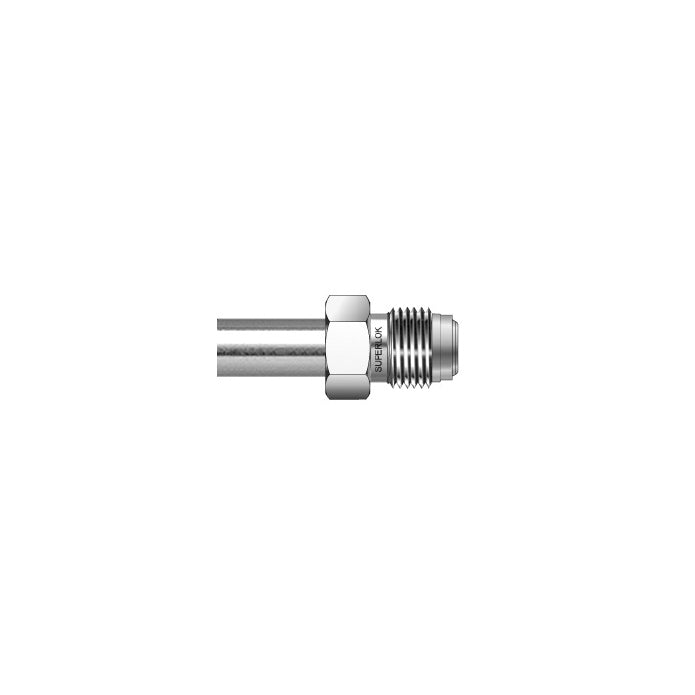

Tube Butt Weld (TBW) Connector - UHP

Can't Find What You're Looking For? Contact Us Here

Description

Description

A Tube Butt Weld (TBW) Connector designed for Ultra High Purity (UHP) applications is a specialized fitting used to join sections of tubing in systems that demand extreme cleanliness and precision.

This connector is intended for applications where a seamless, smooth, and high-integrity connection is necessary. It features a design where the ends of two tubes are aligned and welded together to create a continuous, uninterrupted flow path. This method eliminates potential contamination points and provides a robust connection with minimal risk of leaks.

Typically constructed from high-grade stainless steel, such as 316L, or other materials meeting UHP standards, the TBW Connector ensures that the integrity of the system is maintained. The choice of material is crucial for resisting corrosion and preventing contamination.

The welding process used for the TBW Connector involves aligning the ends of the tubes precisely and performing a butt weld. This welding method ensures a strong, clean joint with a smooth interior surface, which is critical in UHP systems to avoid particle generation and facilitate easy cleaning. The welds are often performed using specialized techniques such as orbital welding to ensure consistency and quality.

Specifications

Specifications

-

CategoryUHP Fittings

-

Sub-CategoryGlands

-

Product TypeButt Weld

-

Fitting ShapeStraight

-

MaterialStainless Steel

-

SeriesSM

-

Data Sheet

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.